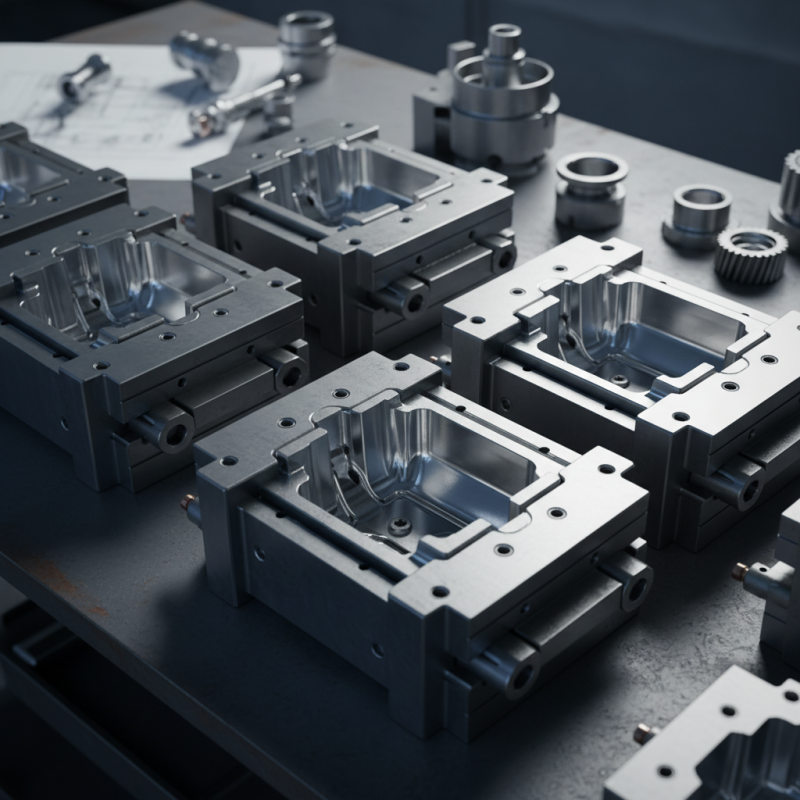

2026 Best Die Casting Molds What to Look For?

Choosing the right Die Casting Molds is crucial for manufacturing success. In 2026, the market offers various options, each with distinct features. Buyers need to consider material, durability, and design.

The complexity of a project often dictates the mold's specifications. Quality molds influence the final product’s precision and performance. It's common for companies to overlook these details. A small mistake can lead to costly production delays.

Understanding different types of molds is necessary. Some molds may not suit specific production needs or materials. Research is vital. Investing time in selecting the best Die Casting Molds can enhance efficiency. The outcome affects not just the product, but the entire workflow. Evaluate your choices carefully.

Essential Features of High-Quality Die Casting Molds for 2026

When selecting die casting molds for 2026, several key features stand out. Quality molds are essential for producing precise and durable components. According to a recent industry report, about 35% of production issues arise from poor mold quality. This statistic highlights the significance of investing in top-notch molds. A well-designed mold reduces the likelihood of defects, saving time and materials.

Material selection is crucial as well. High-quality molds are often made from premium alloys that enhance their longevity and performance. Data shows that molds made from steel can outperform aluminum molds by nearly 25% in terms of lifespan. Additionally, temperature control systems in molds help maintain consistent casting quality. Many manufacturers overlook this aspect, leading to increased scrap rates.

Compatibility with modern casting techniques is another vital factor. Molds must adapt to evolving technologies like low-pressure casting or vacuum die casting. Failure to do so can lead to outdated practices that diminish product quality. While many options exist, not all molds meet the latest industry standards. It's essential to stay informed about these developments, ensuring the selection process aligns with future needs.

Material Selection for Durability and Performance in Die Casting Molds

When selecting materials for die casting molds, durability is key. The right material influences the mold's lifespan and performance. Common choices include steel and aluminum alloys. Steel offers rigidity and wear resistance, while aluminum provides excellent thermal conductivity and lightweight properties. However, each material has its drawbacks. Steel molds can be heavy and difficult to move. Aluminum may warp over time, especially under high heat.

Thermal performance is another crucial factor. Molds that maintain temperature control enhance product quality. Depending on the material, heat transfer rates can vary significantly. This inconsistency can lead to defects in the final product. Consider using coatings to improve heat resistance. They might be costly but could prolong the mold's life.

Always evaluate the mold's expected use. High-volume production demands more robust materials. In contrast, low-volume projects may benefit from lighter, more manageable options. Balancing performance with cost is a challenge. It requires ongoing adjustments based on real-world tests and feedback. Keep in mind that the best choice today may not be ideal tomorrow.

Impact of Mold Design on Production Efficiency and Cost Reduction

Mold design plays a crucial role in die casting efficiency. An optimal mold can enhance production speed and lower costs significantly. According to a recent industry report, companies that invest in advanced mold technology can reduce cycle times by up to 25%. This efficiency translates directly to cost savings, making such investments essential for future competitiveness.

Poor mold design can lead to issues like defects and increased scrap rates. A study revealed that up to 30% of production costs can be attributed to mold-related defects. Keeping molds well-maintained is critical, but even minor design flaws can create significant setbacks. Adjusting wall thickness and eliminating sharp corners can help prevent these problems.

Additionally, the cooling system within the molds must be carefully considered. Inadequate cooling can lead to longer cycle times. An effective cooling strategy can enhance product quality and provide more consistent results. Designers often overlook these factors, but addressing them can improve outcomes. Investing time in thoughtful mold design pays off in the long run. The intersection of good design and production efficiency cannot be ignored.

Impact of Mold Design on Production Efficiency and Cost Reduction

Key Industry Standards and Certifications for Die Casting Molds

When selecting die casting molds, industry standards and certifications play a crucial role. The American Society for Testing and Materials (ASTM) provides guidelines that ensure the quality and durability of mold materials. According to a recent industry report, 80% of manufacturers prefer molds that meet ASTM standards. Compliance with these standards minimizes defects and extends mold life.

Another important aspect is ISO certification. Molds that carry ISO 9001 certification confirm adherence to quality management systems. Research shows that companies with ISO-certified processes experience a 25% reduction in production errors. This certification is vital for maintaining consistency and meeting customer expectations.

However, not all molds meet these standards. Some manufacturers may cut corners, leading to subpar products. It’s essential to conduct thorough inspections and demand transparency from suppliers. Understanding the relevance of these certifications can significantly impact production efficiency and product quality.

2026 Best Die Casting Molds - Key Industry Standards and Certifications for Die Casting Molds

| Mold Material | Mold Type | Certifications | Typical Applications | Average Lead Time |

|---|---|---|---|---|

| Aluminum | High Pressure | ISO 9001, TS16949 | Automotive Parts, Electronics | 4-6 weeks |

| Zinc | Semi-Solid | RoHS, REACH | Consumer Goods, Appliances | 3-5 weeks |

| Magnesium | Low Pressure | ISO 14001, IATF 16949 | Aerospace, Medical Devices | 5-7 weeks |

| Copper | Die Casting | CE, UL | Electrical Components, HVAC | 6-8 weeks |

Emerging Trends in Die Casting Technology and Mold Innovation for 2026

The die casting industry is evolving rapidly. In 2026, staying ahead means embracing new technologies and innovations. Smart molds are emerging, equipped with sensors that provide real-time data. These sensors can monitor temperature and pressure, ensuring better quality control during production.

When choosing die casting molds, consider adaptability. Molds that can accommodate different alloys will remain invaluable. This flexibility reduces costs and time during the manufacturing process. Focus on materials that are durable yet lightweight.

Tip: Look for molds with eco-friendly coatings. They enhance durability and are less harmful to the environment.

Another trend is 3D printing technology. It allows for rapid prototyping of molds. This approach can significantly reduce lead times. Mistakes made during design can be corrected quickly.

Tip: Always consider the cooling system of the mold. Efficient cooling leads to shorter cycle times and improved productivity. Investing in innovative designs and materials will pay off in the long run.