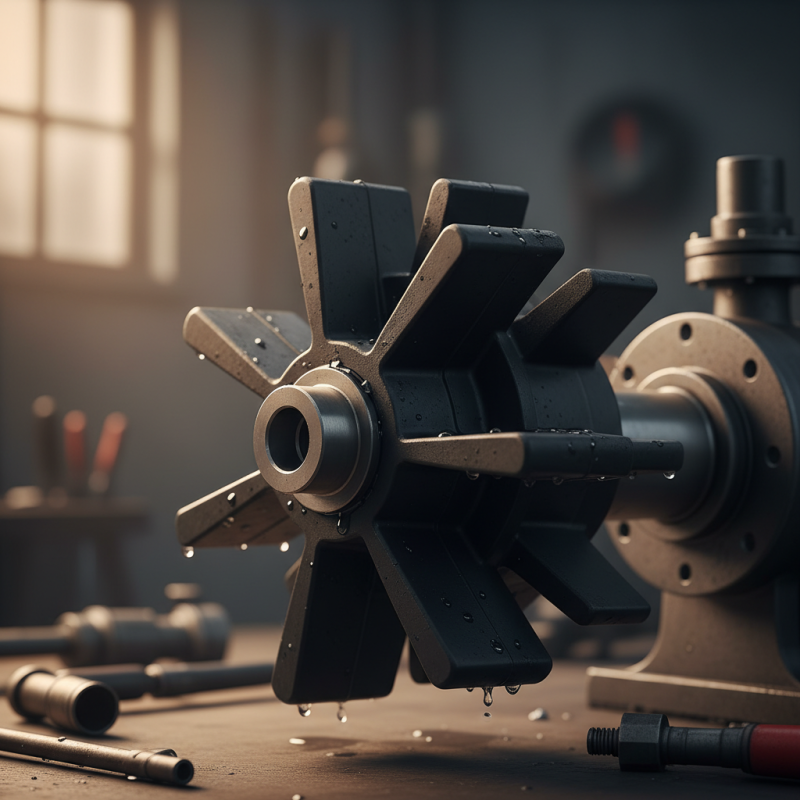

Rubber Pump Impeller Tips for Optimal Performance and Longevity?

In the world of fluid handling, the performance of the Rubber Pump Impeller is often overlooked. John Smith, an industry expert, once stated, "Understanding your impeller can make or break your pump's efficiency." This highlights how critical it is to focus on the details that can enhance both performance and longevity.

Rubber Pump Impellers play a vital role in many applications, yet they face unique challenges. Wear and tear are common enemies. Regular maintenance can drastically improve their lifespan. Choosing the right material is essential. Not all rubbers are created equal. The right selection can prevent premature failure and costly downtime.

Learning the nuances of Rubber Pump Impellers is crucial. Attention to design features, such as blade shape and size, can impact flow rates significantly. Ignoring these aspects might seem trivial, yet they often lead to performance declines. An ill-fitted impeller can cause vibrations, noise, and reduced productivity. Recognizing these factors helps in achieving optimal performance.

Understanding the Role of Rubber Pump Impellers in Fluid Dynamics

Rubber pump impellers are vital components in fluid dynamics. They help in moving fluids efficiently through systems. These impellers are designed to create a specific flow pattern. The shape and material of the impeller influence fluid movement significantly.

When selecting rubber impellers, consider the fluid's viscosity and temperature. The impeller's design should match these parameters closely. An incorrect choice can lead to inefficiencies. It might cause cavitation, reducing performance. Maintenance is another key aspect. Regular checks can identify wear and tear. An overlooked issue can cause large inefficiencies.

The longevity of a rubber pump impeller depends on various factors. Operating conditions play a crucial role. High-pressure and high-temperature environments can accelerate wear. Using the right lubricant can prolong the life of the impeller. Ensure that you regularly monitor these conditions. Ignoring them may lead to unexpected breakdowns.

Factors Influencing the Performance of Rubber Pump Impellers

Rubber pump impellers play a crucial role in overall pump efficiency. Various factors impact their performance and longevity. Material composition is essential. High-quality natural rubber can resist wear and provide flexibility. However, certain harsh environments could degrade standard rubber over time. According to a recent industry report, impellers made from advanced rubber compounds can extend service life by up to 30%.

Moreover, the design of rubber impellers significantly influences performance. A well-designed impeller enhances fluid dynamics. This can lead to reduced energy consumption. Interestingly, studies show that improper sizing of impellers may reduce efficiency by as much as 20%. This highlights the importance of precise engineering in rubber impeller design.

Temperature and pressure conditions also matter. High temperatures can cause rubber to soften or swell. This results in reduced efficiency. An investigation found that operating beyond recommended temperature ranges can shorten the lifespan of rubber impellers. Regular inspections are essential. They help identify signs of wear and avoid unexpected failures. A proactive approach can save costs and ensure operational reliability.

Maintenance Tips for Extending the Life of Rubber Pump Impellers

Rubber pump impellers are vital for effective fluid movement. Maintaining them is crucial for performance and durability. Regular inspection is a fundamental step. Check for wear or damage. Even minor cracks can lead to inefficiency.

Proper lubrication improves functionality. Ensure the right lubricant is used. Too much or too little can create problems. Remember to clean the impellers regularly. Debris buildup can cause uneven performance. Pay attention to unusual sounds during operation. That might indicate underlying issues.

Consider the operating environment. High temperatures can accelerate wear. If possible, adjust the operating settings. Sometimes, it’s necessary to re-evaluate the maintenance routine. A flawed approach may lead to unexpected failures. Prioritize proactive measures to extend the life of your rubber pump impellers.

Common Issues with Rubber Pump Impellers and Their Solutions

Rubber pump impellers play a crucial role in fluid transfer. However, they can face common issues that affect their efficiency. One prevalent problem is wear and tear caused by abrasive materials in the fluid. This can lead to reduced performance and a shorter lifespan for the impeller. Regular inspections are essential to identify signs of wear. Replacing worn impellers promptly can prevent further damage.

Another issue is cavitation, which occurs when vapor bubbles collapse around the impeller. It can cause significant damage over time. To mitigate cavitation, ensure that the pump is properly sized for the application. This includes checking for adequate fluid levels and avoiding sudden changes in flow rate.

Lastly, improper installation can lead to misalignment and excessive vibration. This can damage the impeller and other components. Always follow installation guidelines carefully. Taking the time to address these common issues can lead to improved performance and longevity for rubber pump impellers. Attention to detail is critical in maintaining overall efficiency.

Best Practices for Selecting the Right Rubber Pump Impeller for Your Needs

Choosing the right rubber pump impeller is crucial for efficiency. The right impeller can improve flow rates significantly. Industry reports show that an optimized impeller can raise efficiency by up to 15%. This not only saves energy but reduces costs.

Consider key factors like fluid type and impeller size. A common error is ignoring the viscosity of the fluid handled. Rubber impellers work well with various fluids, yet they may degrade faster when exposed to harsh chemicals. Selecting the wrong material could lead to premature failure. Remember, durability matters just as much as fit.

Conducting regular maintenance checks is essential. Studies reveal that 40% of pump failures occur due to impeller wear. Monitoring the condition of your rubber impeller can prevent unexpected downtimes. In the long run, investing time in selecting and maintaining your impeller pays off. A better choice now can lead to many successful operations ahead.