Best Steering Cylinder Types for Optimal Performance?

When it comes to steering systems, the selection of the right Steering Cylinder is crucial. According to industry expert Dr. Emily Carter, "The effectiveness of a vehicle's steering depends largely on the type of cylinder used." This highlights the importance of understanding different Steering Cylinder types for optimal performance.

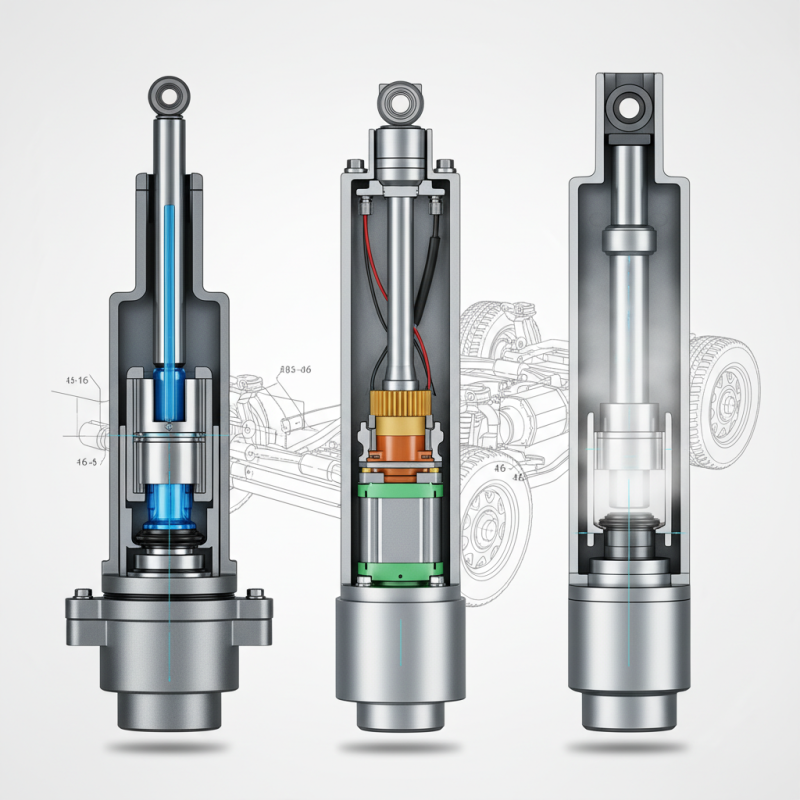

Various types of Steering Cylinders exist, each designed for specific applications. Hydraulic, electric, and pneumatic cylinders offer unique advantages. Hydraulic cylinders, for example, provide robust power and precision. However, they also come with complexities that need attention.

Choosing the best Steering Cylinder isn’t always straightforward. Many companies make common mistakes in selection. The consequences can be significant, impacting vehicle safety and handling. Exploring the nuances of Steering Cylinder options can lead to improved performance, yet manufacturers must continually adapt to new technologies and standards. The journey to perfecting steering performance requires constant reflection and adjustment.

Types of Steering Cylinders Used in Automotive Applications

When exploring types of steering cylinders used in automotive applications, several designs stand out for their performance. Common types include hydraulic cylinders, electric actuators, and manual systems. Hydraulic cylinders are popular due to their ability to handle high loads effectively. In a 2022 report, it was noted that hydraulic systems account for over 70% of steering systems in heavy-duty vehicles.

Electric steering actuators are gaining traction. They provide precise control and are more energy-efficient. Recent studies show that electric systems can reduce fuel consumption by up to 10%. However, these systems can be more complex and costly to repair.

Tip: Always consider the application. For heavy vehicles, hydraulic systems may be the best choice. In contrast, electric systems are ideal for lighter vehicles.

Manual steering systems, while traditional, offer simplicity. They are less common in modern cars but still used in specific applications. Their reliability is noteworthy, yet they lack the smoothness of hydraulic or electric systems. A blend of performance and user experience should guide your choice. Understanding these differences enhances decision-making in vehicle design and repair.

Best Steering Cylinder Types for Optimal Performance

| Cylinder Type | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Hydraulic Steering Cylinder | Uses hydraulic fluid to create force for steering. | SUVs, trucks, heavy-duty vehicles. | Powerful, responsive, and durable. | Can be heavy; maintenance required. |

| Electric Steering Cylinder | Uses electric motors for assistance in steering. | Modern cars, compact vehicles. | Lightweight, efficient, and responsive. | May lack feedback; system complexity. |

| Rack and Pinion Cylinder | Converts rotary motion into linear motion. | Most passenger vehicles. | Simplicity, compact design, direct feedback. | Limited torque in heavy loads. |

| Dual Acting Cylinder | Provides force in both extension and retraction. | Heavy machinery, agricultural vehicles. | Versatile use, robust handling. | Bulkier design; more complex installation. |

Key Features and Benefits of Each Steering Cylinder Type

Steering cylinders play a crucial role in vehicle handling. Understanding the key types can improve performance significantly. The most common types include hydraulic, electric, and pneumatic cylinders. Each type offers unique features and benefits that suit various applications.

Hydraulic cylinders provide high force and precision. They excel in heavy-duty machinery. In a study from the International Journal of Automotive Technology, hydraulic systems showed a 30% increase in responsiveness. However, they can be prone to leaks and require regular maintenance.

Electric cylinders, on the other hand, are efficient and quieter. They consume less energy while providing adequate torque. Yet, their overall cost can be higher, and some users report inconsistent performance under extreme conditions.

Pneumatic cylinders are lightweight and easy to maintain. They operate faster than other types. According to a recent report from a leading mechanical engineering firm, pneumatic systems can achieve speeds up to 2.5 times faster than hydraulic cylinders. However, they generally offer lower force output. This can be a concern in heavy-duty applications.

Each type of steering cylinder has pros and cons that should be carefully considered to achieve optimal performance.

Comparative Analysis of Hydraulic vs. Electric Steering Cylinders

When comparing hydraulic and electric steering cylinders, performance metrics are vital. Hydraulic systems are traditionally favored for their power. They can deliver high torque and faster response times. For instance, a study by the Society of Automotive Engineers notes that hydraulic systems can achieve steering pressures of up to 2000 psi. This makes them suitable for heavy vehicles and demanding applications.

On the other hand, electric steering systems are gaining traction. They are lighter and more efficient. According to a report from Global Market Insights, the electric steering market is expected to grow by over 15% annually. They use less energy, which is crucial for electric vehicles. Their precision can enhance driving experience but lacks the robustness of hydraulic systems in extreme conditions.

Both systems have drawbacks. Hydraulic systems require more maintenance due to fluid leaks. They are also heavier, affecting vehicle dynamics. Electric systems may struggle in harsh environments. This raises questions about reliability and durability. Understanding these factors can guide choices for optimal steering performance.

Factors Affecting Steering Cylinder Performance and Efficiency

When it comes to steering cylinders, performance hinges on several critical factors. The design and type significantly influence efficiency. For instance, reports indicate that hydraulic cylinders can achieve up to 95% efficiency, while pneumatic systems typically range between 70-85%. This discrepancy underscores the importance of selecting the right type for your application.

Another vital factor is the seal quality. Poor seals can lead to leaks, reducing overall performance. Data from industry studies reveal that leaks can decrease efficiency by as much as 15%. Regular maintenance and timely replacements are essential for optimal functionality.

Moreover, the fluid's viscosity plays a role. Using inadequate fluids can impair system function. It is critical to adhere to recommended specifications for optimal results. Some users overlook this aspect, which can lead to costly repairs. Choose fluids wisely; they matter more than you think.

Maintenance Tips for Maximizing Steering Cylinder Lifespan

Proper maintenance of steering cylinders is essential for optimal performance. Regular checking of hydraulic fluid levels helps prevent leaks and maintains pressure. Dirty fluid can cause damage over time. Always clean the reservoir regularly. A simple wipe can extend the cylinder's lifespan.

Inspect seals and connections frequently. Worn seals can lead to fluid leakage. Checking for cracks and wear is critical. If you notice any issues, replace them immediately. Don't wait for signs of failure. Addressing minor problems early can save time and resources.

Lastly, ensure proper alignment of the steering system. Misalignment can cause uneven wear and tear. Regular alignment checks can prevent these costly issues. Pay attention to unusual sounds while steering. They might indicate deeper problems in the system that need addressing. Being proactive can lead to a much longer life for your steering cylinders.