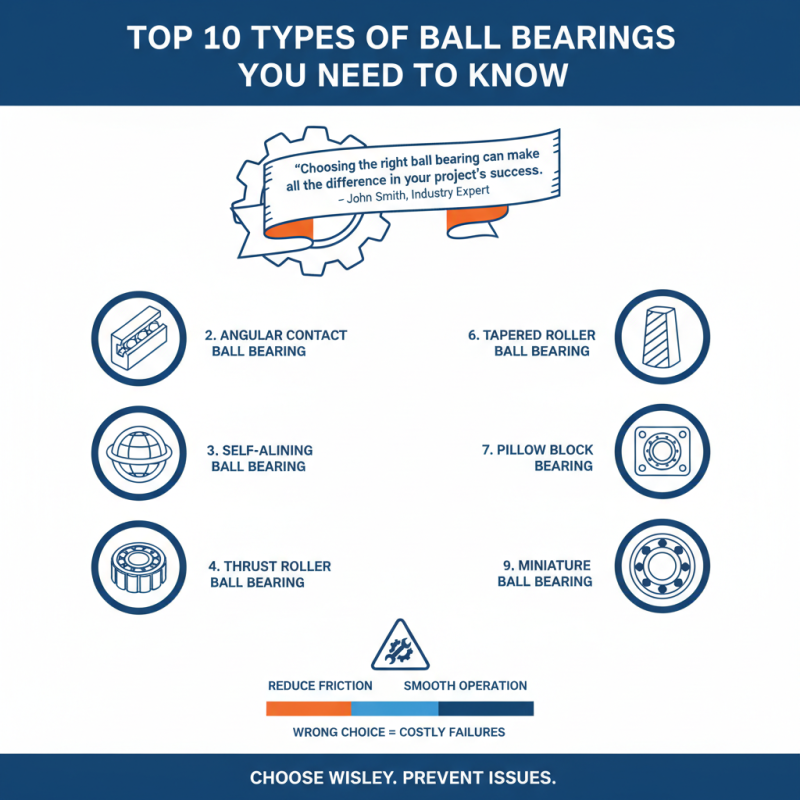

Top 10 Types of Ball Bearings You Need to Know?

In the world of engineering, Ball Bearings play a crucial role in enhancing performance and efficiency. According to John Smith, a renowned expert in the ball bearing industry, “Choosing the right ball bearing can make all the difference in your project’s success.” This highlights the importance of understanding the various types available.

There are many different types of ball bearings, each designed for specific applications. These components reduce friction and ensure smooth operation in machines. However, many people underestimate their significance.

Understanding ball bearings requires knowledge and attention. Not every type suits every application. Using the wrong bearing can lead to costly failures. As you navigate through the types, consider your needs carefully. Choosing wisely can prevent unforeseen issues in the long run.

Types of Ball Bearings: An Overview of Common Types

When it comes to ball bearings, understanding the types is crucial. These small components play a significant role in reducing friction. There are several common types. Deep groove ball bearings are widely used. Their versatile design allows for radial and axial loads. They are reliable in many applications.

Another type is angular contact ball bearings. These bearings can handle higher speeds and axial loads from one direction. They are often found in machine tools and robotics. Then we have self-aligning ball bearings. They can accommodate misalignment, making them useful in various setups. This feature can be a lifesaver in real-world applications.

Thrust ball bearings are designed to handle axial loads only. They are commonly used in automotive gear assemblies. Lastly, you might encounter miniature ball bearings. They are essential in small devices, like electronics. Each type has its advantages and limitations. Choosing the right one can be tricky, and a poor choice might lead to early failures or inefficiencies. It's vital to analyze the specific needs of your project carefully.

Deep Groove Ball Bearings: Versatility and Applications

Deep groove ball bearings are among the most common types of ball bearings used today. Their simple design allows for versatility in applications, making them a top choice across various industries. According to a recent industry report, deep groove ball bearings account for over 40% of the total bearing market. They are often found in electrical motors, automotive applications, and even household appliances.

One key to their popularity is their ability to handle both radial and axial loads. This dual functionality makes them ideal for diverse applications. They can operate smoothly at high speeds and can withstand a range of environmental conditions. For many engineers, deep groove ball bearings are the go-to solution for reliability in mechanical designs.

**Tips:** When selecting deep groove ball bearings, consider the operating environment. Factors like temperature and contamination levels can impact performance. Also, assess the load requirements precisely. Underestimating these can lead to premature failure, prompting a need for analysis of the bearing's lifespan. Remember, matching the right type to your application is crucial for efficiency.

Angular Contact Ball Bearings: Design and Uses

Angular contact ball bearings are essential in various mechanical systems. Their unique design allows them to accommodate both radial and axial loads. This feature makes them ideal for applications that require support for high-speed operations. When installed, these bearings allow for precise rotational movements, which is critical in industries like aerospace and manufacturing.

The inner and outer ring of angular contact bearings are not parallel. Instead, they are arranged at an angle. This design helps distribute the load across the bearing, enhancing its durability. However, improper installation can lead to misalignment, resulting in premature wear. Regular maintenance is crucial to ensure optimal performance. Without it, the benefits of these bearings can be easily lost.

Applications of angular contact ball bearings include milling machines and electric motors. They are also found in robotics, where precision is key. Each application might require specific designs, which can complicate the selection process. It’s important to analyze the requirements carefully. Consider the environment and load conditions as well. Ignoring these factors can lead to less than ideal outcomes.

Self-Aligning Ball Bearings: Features and Benefits

Self-aligning ball bearings are designed to accommodate misalignment. This feature is vital in applications where shaft alignment is difficult. They consist of two rows of balls. The inner ring has a spherical shape. This design allows for adjustments to angular errors effectively.

One significant benefit is their ability to reduce wear. When misalignment occurs, traditional bearings often fail or wear out quickly. Self-aligning ball bearings extend the lifespan of machinery significantly. They can handle loads in multiple directions, which is useful in diverse industrial scenarios. However, they may require proper installation to maximize their benefits.

Not all self-aligning bearings perform equally under stress. Some may not handle extreme loads effectively. It's crucial to consider the specific application before selecting them. Regular maintenance can also impact performance. Users need to be vigilant about checking their condition. Ignoring small issues can lead to bigger problems down the line.

Thrust Ball Bearings: How They Manage Axial Loads

Thrust ball bearings play a crucial role in handling axial loads. They are specifically designed to support forces that act along the shaft's axis. The unique construction of these bearings allows them to operate smoothly under high thrust levels. They typically consist of two rings and a set of balls arranged within. This simple design is effective, yet it has its limitations.

One common concern is their inability to handle radial loads. This means thrust ball bearings are not suitable for every application. Users must consider axial load limits to avoid premature failure. Regular maintenance is essential for optimal performance. Any slight misalignment could lead to uneven wear or noise.

Despite their effectiveness, they are not perfect. What if the axial load exceeds the rating? This can cause severe damage, rendering the bearing useless. Additionally, lubrication plays a pivotal role. Insufficient lubrication can lead to overheating and failure. Always remember, even small changes can impact performance significantly.